In the production process of barrels, broaching plays a critical role in ensuring both safety and the quality of the final product. In advanced markets, especially in Central and Northern Europe, safety is increasingly tied to the complexity of profiles and the ability to differentiate them in a controlled and repeatable manner.

Giuliani manages this level of complexity thanks to a broaching machine that allows machining differentiated profiles in a structured and controllable way.

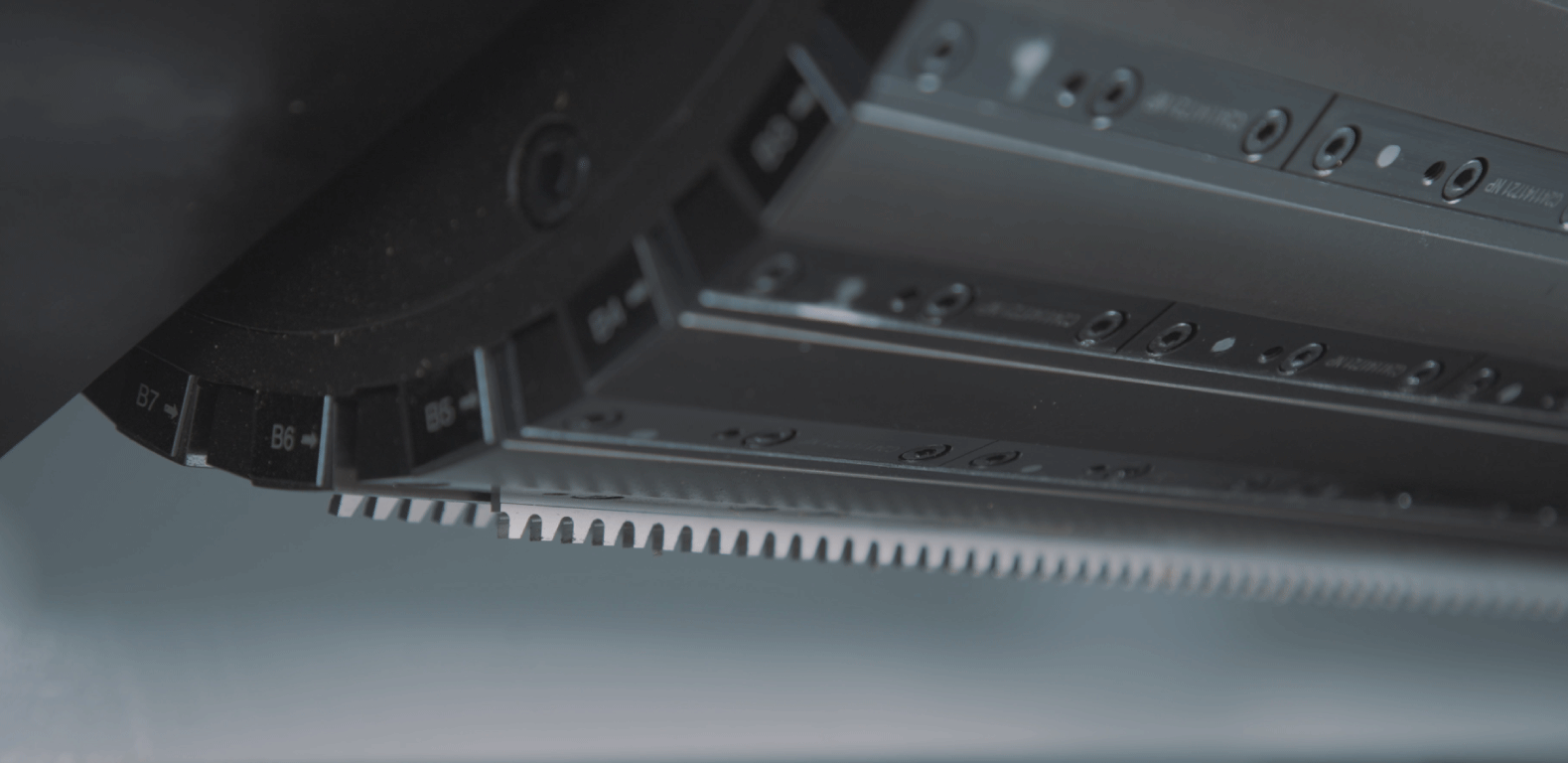

The BX Giuliani philosophy is based on a modular approach to broaching. The machine can be configured with one or more drums, adapting to different levels of production complexity.

The primary drum makes it possible to produce the master profile, removing most of the material progressively. Starting from this base, it is possible to add auxiliary drums dedicated to variants, which act with targeted micro-removals.

This approach makes it possible to achieve a high number of profile combinations starting from a common structure, meeting the needs of those markets where safety is strongly influenced by the configuration of the key entry profile.

Discover how BX Giuliani manages profile complexity in a flexible and configurable way.

One of the most relevant design elements of BX Giuliani is the drum length. The primary drum reaches 1600 mm, a size significantly larger than many traditional solutions.

This choice makes it possible to distribute material removal over a greater length, achieving a more gradual and stable cut. The result is better profile quality, a reduction in stresses and consequently a longer broaching tool life.

Completing this approach, machining is performed dry, helping to reduce management complexity and the variables that can affect process stability and repeatability.

BX Giuliani is designed around a rigid mechanical structure, intended to minimize any deformation during machining. This structural rigidity is a key element to ensure precision and consistency across the parts produced.

Each drum is managed by an independent CNC control, which allows micro-adjustments on three axes: vertical, horizontal and rotation. During the initial set-up, all the tool positions are stored in the machine software. At tool change, the numerical control automatically recalls the saved settings, eliminating manual adjustments and significantly reducing setup times.

Compared to traditional broaching machines, this approach makes it possible to avoid downtime related to tool change and to keep the process under control even in complex production runs.

Discover the design solutions that enable BX Giuliani to maintain precision and control in the broaching process.

BX Giuliani integrates functions that directly support finished product quality and production management. The laser marking system makes it possible to mark on the side of the barrel the profile code produced, facilitating identification and traceability.

The automatic deburring option intervenes to remove any machining residues from the pin holes and from the barrel tail, contributing to a higher quality level.

The Giuliani broaching machine is designed for manufacturers looking for a machine capable of offering precision, flexibility and control over time, and who recognize the value of an architecture designed for quality.

The combination of rigid structure, tool length and gradual cut management gives BX Giuliani technological potential that goes beyond the most common applications. This set of design choices opens up the possibility of tackling machining on more demanding materials than standard brass, maintaining process stability and controllability.

An aspect that represents a starting point for further insights, also in relation to different application and production contexts. Explore the BX broaching solution with the Giuliani Team.