In an industry where high productivity and pinpoint precision are critical, the choice of manufacturing technology can be a game-changer.

Giuliani Transfer Machines stand out for their efficiency, speed, and reliability, optimizing production cycles and minimizing downtime.

Let’s explore why they represent a smart, strategic investment in Automotive component manufacturing.

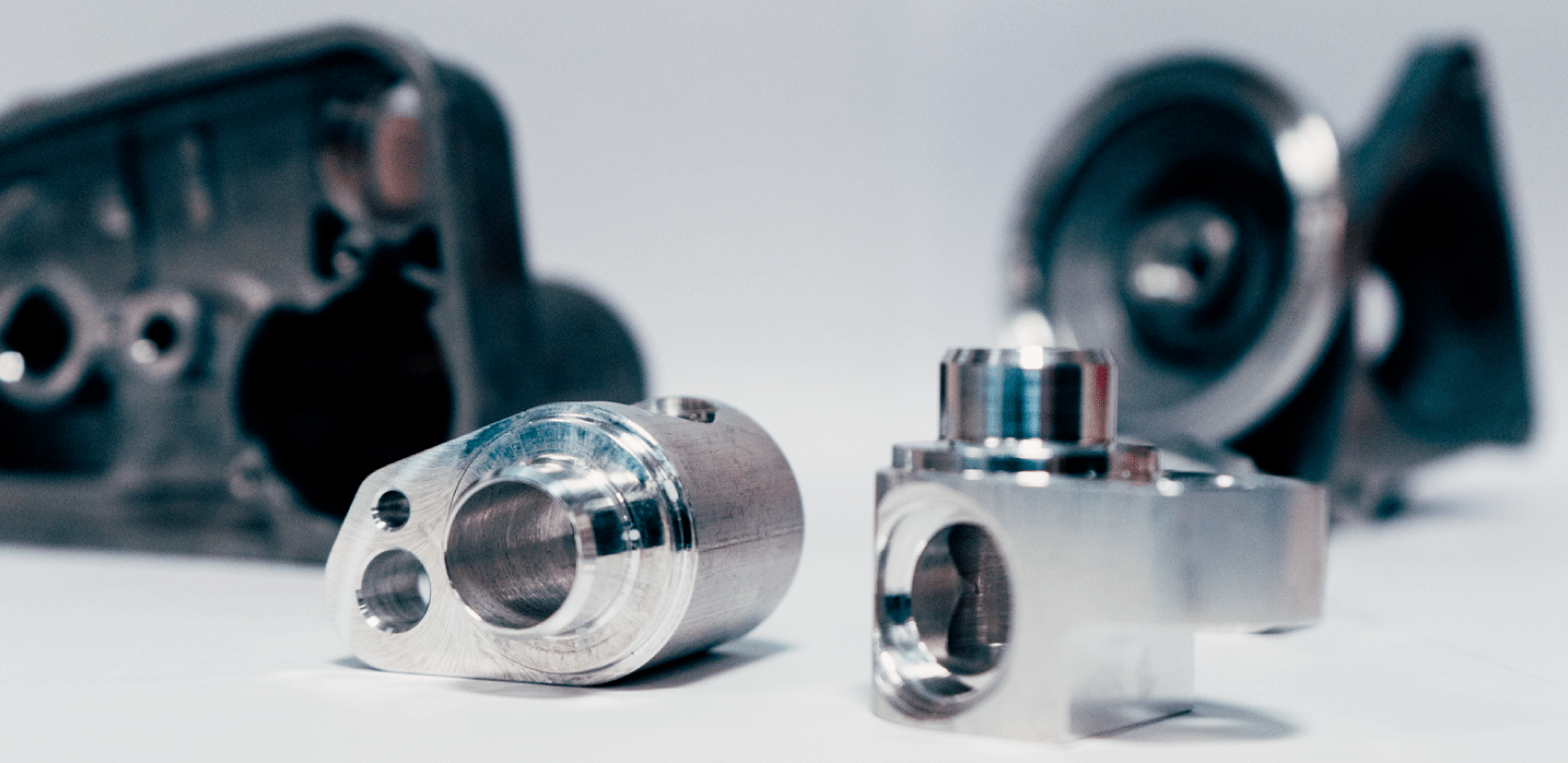

In the Automotive industry, components must be manufactured with minimal cycle times to meet the demands of high-volume production. Transfer Machines deliver a strategic edge by carrying out multiple machining operations simultaneously on a single workpiece, drastically reducing processing time compared to conventional machining centers, which operate sequentially.

Key benefits for Automotive component manufacturers:

Thanks to advanced technology, Giuliani Transfer Machines, enable manufacturers to meet market demands swiftly and cost-effectively—without compromising quality.

In the Automotive sector, quality and reliability are non-negotiable. Even minimal deviations can jeopardize vehicle safety and assembly integrity. Giuliani Transfer Machines ensure a stable, tightly controlled process that delivers strict tolerances on every unit produced.

Compared to traditional machining centers, Transfer Machines offer:

Integrating Transfer Machines not only enhances component quality but also reduces production costs, boosting both efficiency and sustainability.

One of the most important factors in choosing a manufacturing solution is the balance between initial capital investment and ongoing operating expenses. While a Transfer Machine requires a higher upfront investment compared to a single machining center, its total cost of ownership over time proves substantially lower.

Why Giuliani Transfer Machines are the most cost-effective choice:

Automotive companies must strike a balance between productivity and economic efficiency. Giuliani Transfer Machines offer a high return on investment and significantly lower long-term operational costs.

In the fast-paced Automotive sector, where maximum productivity must be achieved without sacrificing quality, Giuliani Transfer Machines offer a winning combination.

With outstanding performance, unwavering reliability, and reduced production costs, Giuliani Transfer solutions allow manufacturers to respond swiftly and efficiently to market demands. Investing in this technology means adopting an advanced solution that ensures production efficiency, operational stability, and cost optimization.

For Automotive manufacturers, Giuliani Transfer technology is more than a smart choice—it’s a true strategic advantage that drives higher productivity, lowers costs, and enhances component quality.